-

Home

-

About Us

-

Products

- Butterfly Valve

- Triple Offset Butterfly Valve

- Double Eccentric Butterfly Valve

- Resilient Seated Butterfly Valve

- High Performance Butterfly Valve

- Ball Valve

- Threaded Ball Valve

- SW/BW Ball Valve

- Floating Ball Valv

- Trunnion Ball Valve

- Full Welded Ball Valve

- Gate Valve

- Forged Gate Valve

- Casting Steel Gate Valve

- Casting Iron Gate Valve

- Knife Gate Valve

- Globe Valve

- Forged Globe Valve

- Casting Steel Globe Valve

- Casting Iron Globe Valve

- Check Valve

- Forged Check Valve

- Lift Check Valve

- Swing Check Valve

- Disc Check Valve

- Butterfly Type Check Valve

- Silent Check Valve

- Rubber Disc Check Valve

- Hydraulic Control Valve

- Fixed Cone Valve

- Plunger Valve

- Hydraulic Valve

- Air Vent Valve

- Plug Valve

- Lubricated Plug Valve

- Non-lubricated Plug Valve

- Actuators

- Pneumatic Actuator

- Electrical Actuator

- Hydraulic Actuator

- Pipe Fitting

- Joints

- Flanges

- Strainer

-

Applications

- Industry

- Water and Wastwater

- Oil and Gas

- Chemical and Petrochemical

- Mining and Metal

- Food and Drinking

- Slurry and Paper

- Power

- Marines

-

Resources

-

Home

-

About Us

-

Products

- Butterfly Valve

- Triple Offset Butterfly Valve

- Double Eccentric Butterfly Valve

- Resilient Seated Butterfly Valve

- High Performance Butterfly Valve

- Ball Valve

- Threaded Ball Valve

- SW/BW Ball Valve

- Floating Ball Valv

- Trunnion Ball Valve

- Full Welded Ball Valve

- Gate Valve

- Forged Gate Valve

- Casting Steel Gate Valve

- Casting Iron Gate Valve

- Knife Gate Valve

- Globe Valve

- Forged Globe Valve

- Casting Steel Globe Valve

- Casting Iron Globe Valve

- Check Valve

- Forged Check Valve

- Lift Check Valve

- Swing Check Valve

- Disc Check Valve

- Butterfly Type Check Valve

- Silent Check Valve

- Rubber Disc Check Valve

- Hydraulic Control Valve

- Fixed Cone Valve

- Plunger Valve

- Hydraulic Valve

- Air Vent Valve

- Plug Valve

- Lubricated Plug Valve

- Non-lubricated Plug Valve

- Actuators

- Pneumatic Actuator

- Electrical Actuator

- Hydraulic Actuator

- Pipe Fitting

- Joints

- Flanges

- Strainer

-

Applications

- Industry

- Water and Wastwater

- Oil and Gas

- Chemical and Petrochemical

- Mining and Metal

- Food and Drinking

- Slurry and Paper

- Power

- Marines

-

Resources

PRODUCT DETAILS

High Performance Butterfly Valve

Technical Data

| Size range | Body Material |

| 2"~60"(DN50~DN1500) | Carbon Steel, Stainless Steel, Al-bronze etc. |

| Temperature range | Stem Material |

| -62°F to 500°F (-52°C to 260°C) | Stainless Steel |

| Pressure ratings | Disc Material |

| Up to ASME Class 300Lb (PN50) | Stainless Steel, Al-bronze etc. |

| Shuttoff ratings | Seat Material |

| Bidirectional Bubble-tight | R-PTFE, PPL etc. |

| Design & Manufacturing | Face to Face |

| API 609, EN593, JISB2032, GB/T12238, | API 609, EN558, JISB2002, GB/T12221 |

| End connection | Test & Inspection |

|

ASME B16.1 Class 125, ASME B16.5 Class 150, EN 1092 PN10, PN16, GB/T 17241, GB/T 9113, JIS B2220 |

MSS SP-61, API 598, EN 12266-1,JIS B2003, GB/T13927 |

Features and Benefits

Huanqiu's High Performance Butterfly Valve is a true marvel of engineering, designed to deliver exceptional performance and reliability in the most demanding industrial applications. As one of the leading high performance butterfly valve manufacturers, we pride ourselves on delivering the highest quality products at competitive prices.

Featuring a Double Offset design, our High Performance Butterfly Valve is the perfect choice for applications that demand precise control, high flow rates, and minimal pressure drop. With its superior performance and durability, this valve has become the go-to choice for industries ranging from chemical processing and power generation to water treatment and more.

Design

Huanqiu's high performance Butterfly Valve's full-faced retainer is bolted to the body, locking the seat in the correct position. The seat is secured even without the mating flange.

The closely confined and well supported seat is energized by the disc and line pressure. The higher the pressure, the tighter the seal. In low pressure and vacuum applications, the energized seat offers superior sealing and longer service life than many other designs. Line media is sealed to zero-leakage in both directions.

Seat replacement is extremely easy. Just remove the seat retainer, rotate the disc into the closed position and place a new seat assembly in the machined recess of the body. This simple procedure will not disturb the disc or stem.

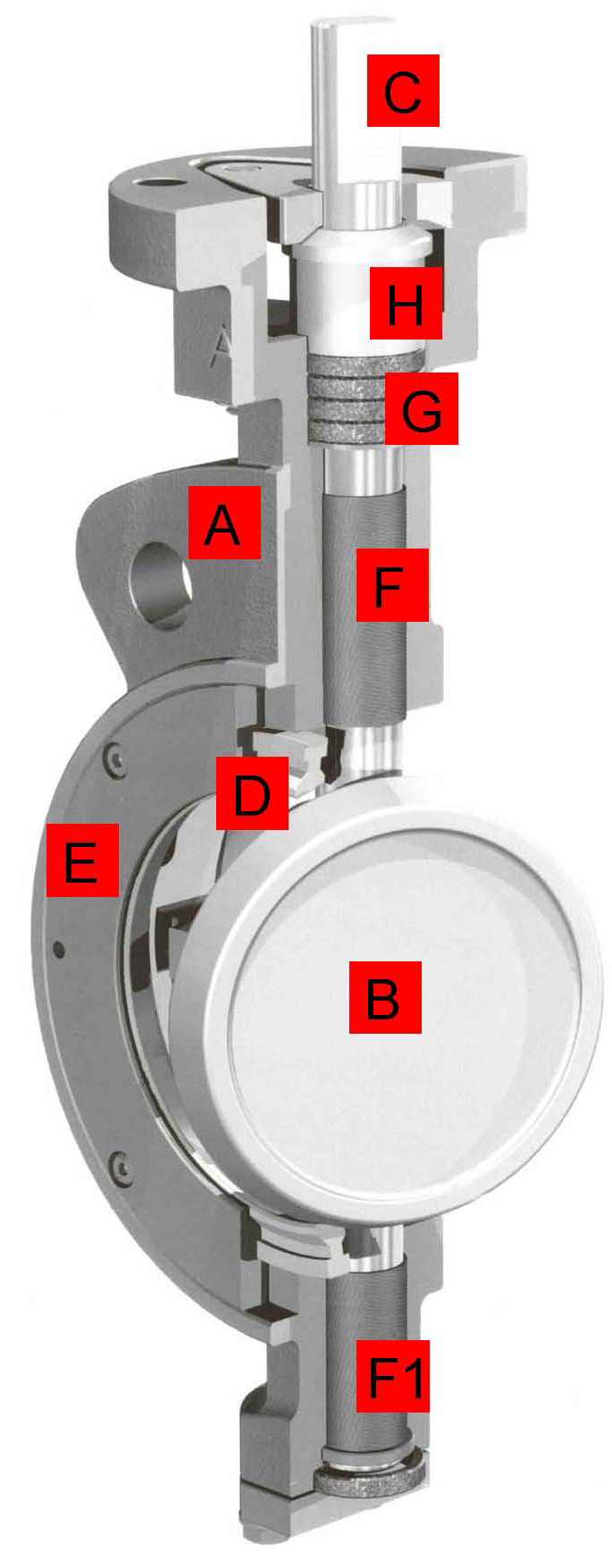

| A BODY: Heavy duty body, double offset type. |

| B DISC: Soild stainless steel. |

|

C STEM: one-piece stem with a blowout prevention ring located bottom, The high-strength, one piece stem is 17-4 Ph Stainless Steel. The valve stem is standardized for interchangeability of actuators. |

| D SEAT: Fully replaceable Energizer encapsulated in RTFE. |

|

E SEAT RETANIER: Retainer is firmly attached by bolts located outside of sealing area, protecting the bolts from corrosion. |

|

F Top bearings: consisting of a 316 Stainless Steel shell with a TFE/glass fabric liner bearing surface securely support the stem. The stem bearings provide excellent resistance to corrosion and distortion from high temperatures and mechanical loading forces. |

| F 1 Bottom bearings. |

|

G Packing: The stem packing system features easy access to adjusting hex head nuts without requiring removal of the actuator. The system consists of a gland ring, a gland retainer, studs, hex head nuts and lock washers. |

| H Packing Gland: stainelss steel. |

Download catalogue here

Butterfly Valve

Products